Induction motor

An induction or asynchronous motor is a type of AC motor where power is supplied to the rotor by means of electromagnetic induction. These motors are widely used in industrial drives, particularly polyphase induction motors, because they are rugged and have no brushes. Single-phase versions are used in small appliances. Their speed is determined by the frequency of the supply current, so they are most widely used in constant-speed applications, although variable speed versions, using variable frequency drives are becoming more common. The most common type is the squirrel cage motor, and this term is sometimes used for induction motors generally.

Contents |

History

The idea of a rotating magnetic field was developed by François Arago in 1824,[1] and first implemented by Walter Baily.[2] Based on this, practical induction motors were independently invented by Nikola Tesla in 1883 and Galileo Ferraris in 1885.[3] According to his 1915 autobiography Tesla conceived the rotating magnetic field in 1882 and used it to invent the first induction motor in 1883;[4] Ferraris developed the idea in 1885.[5] In 1888, Ferraris published his research to the Royal Academy of Sciences in Turin, where he detailed the foundations of motor operation;[6] Tesla, in the same year, was granted U.S. Patent 381,968 for his motor. The induction motor with a cage was invented by Mikhail Dolivo-Dobrovolsky a year later.

Operation

In both induction and synchronous motors, the stator is powered with alternating current (polyphase current in large machines) and designed to create a rotating magnetic field which rotates in time with the AC oscillations. In a synchronous motor, the rotor turns at the same rate as the stator field. By contrast, in an induction motor the rotor rotates at a slower speed than the stator field. Therefore the magnetic field through the rotor is changing (rotating). The rotor has windings in the form of closed loops of wire. The changing magnetic flux induces currents in the windings as in a transformer, and these currents create their own magnetic fields. These interact with the stator field to create torque to turn the rotor.

For these currents to be induced, the speed of the physical rotor must be lower than that of the stator's rotating magnetic field ( ), or the magnetic field would not be moving relative to the rotor conductors and no currents would be induced. As the speed of the rotor drops below synchronous speed, the rotation rate of the magnetic field in the rotor increases, inducing more current in the windings and creating more torque. The ratio between the rotation rate of the magnetic field as seen by the rotor (slip speed) and the rotation rate of the stator's rotating field is called "slip". Under load, the speed drops and the slip increases enough to create sufficient torque to turn the load. For this reason, induction motors are sometimes referred to as asynchronous motors.[7] An induction motor can be used as induction generator, or it can be unrolled to form the linear induction motor which can directly generate linear motion.

), or the magnetic field would not be moving relative to the rotor conductors and no currents would be induced. As the speed of the rotor drops below synchronous speed, the rotation rate of the magnetic field in the rotor increases, inducing more current in the windings and creating more torque. The ratio between the rotation rate of the magnetic field as seen by the rotor (slip speed) and the rotation rate of the stator's rotating field is called "slip". Under load, the speed drops and the slip increases enough to create sufficient torque to turn the load. For this reason, induction motors are sometimes referred to as asynchronous motors.[7] An induction motor can be used as induction generator, or it can be unrolled to form the linear induction motor which can directly generate linear motion.

Synchronous speed

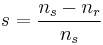

The synchronous speed of an AC motor is the rotation rate of the rotating magnetic field created by the stator. It is always an integer fraction of the supply frequency. The synchronous speed ns in revolutions per minute (RPM) is given by

where f is the frequency of the AC supply current in Hz and p is the number of magnetic pole pairs per phase.[8] For example, a small 3-phase motor typically has six magnetic poles organized as three opposing pairs 120° apart, each powered by one phase of the supply current, so there is one pole pair per phase and p = 1. For 60 Hz supply frequency, its synchronous speed is thus 3600 RPM. Under no-load conditions, when the only load on the motor is its friction, the speed approaches synchronous speed.

Slip

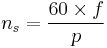

Slip s is the ratio of the rotation rate of the rotor magnetic field to the rotation rate of the stator magnetic field

where  is the rotor rotation speed in rpm.[9] It is zero at synchronous speed and 1 (100%) when the rotor is stationary. The slip determines the motor's torque. Since the short-circuited rotor windings have small resistance, a small slip induces a large current in the rotor and produces large torque.[10] At full rated load, typical values of slip are 4-6% for small motors and 1.5-2% for large motors, so induction motors have good speed regulation and are considered constant-speed motors.

is the rotor rotation speed in rpm.[9] It is zero at synchronous speed and 1 (100%) when the rotor is stationary. The slip determines the motor's torque. Since the short-circuited rotor windings have small resistance, a small slip induces a large current in the rotor and produces large torque.[10] At full rated load, typical values of slip are 4-6% for small motors and 1.5-2% for large motors, so induction motors have good speed regulation and are considered constant-speed motors.

Torque curve

The torque exerted by the motor as a function of slip is given by a torque curve. Over a motor's normal load range, the torque line is close to a straight line, so the torque is proportional to slip.[11] As the load increases above the rated load, increases in slip provide less additional torque, so the torque line begins to curve over. Finally at a slip of around 20%[10] the motor reaches its maximum torque, called the "breakdown torque". If the load torque reaches this value, the motor will stall. At values of slip above this, the torque decreases. In 3-phase motors the torque drops but still remains high at a slip of 100% (stationary rotor). Therefore the starting torque of an induction motor is less than other types of motor, but still around 300% of rated torque.[11] In 2-pole single-phase motors, the torque goes to zero at 100% slip (zero speed), so these require alterations to the stator such as shaded poles to provide starting torque.

Construction

The stator of an induction motor consists of poles carrying supply current to induce a magnetic field that penetrates the rotor. To optimize the distribution of the magnetic field, the windings are distributed in slots around the stator, with the magnetic field having the same number of north and south poles. Induction motors are most commonly run on single-phase or three-phase power, but two-phase motors exist; in theory, induction motors can have any number of phases. Many single-phase motors having two windings can be viewed as two-phase motors, since a capacitor is used to generate a second power phase 90 degrees from the single-phase supply and feeds it to the second motor winding. Single-phase power is more widely available in residential buildings, but cannot produce a rotating field in the motor, so they must incorporate some kind of starting mechanism to produce a rotating field. There are three types of rotor: squirrel cage rotors made up of skewed (to reduce noise) bars of copper or aluminum that span the length of the rotor, slip ring rotors with windings connected to slip rings replacing the bars of the squirrel cage, and solid core rotors made from mild steel.

Speed control

The theoretical unloaded speed (with slip approaching zero) of the induction motor is controlled by the number of pole pairs and the frequency of the supply voltage.

When driven from a fixed line frequency, loading the motor reduces the rotation speed. When used in this way, induction motors are usually run so that in operation the shaft rotation speed is kept above the peak torque point; then the motor will tend to run at reasonably constant speed. Below this point, the speed tends to be unstable and the motor may stall or run at reduced shaft speed, depending on the nature of the mechanical load.

Before the development of semiconductor power electronics, it was difficult to vary the frequency, and induction motors were mainly used in fixed speed applications. However, many older DC motors have now been replaced with induction motors and accompanying inverters in industrial applications.

Equivalent circuit

The equivalent circuit of an induction motor has the equivalent resistance of the stator on the left, consisting of the copper and core resistance in series, as  . During operation, the stator induces reactance, represented by the inductor

. During operation, the stator induces reactance, represented by the inductor  .

.  represents the effect of the rotor passing through the stator's magnetic field. The effective resistance of the rotor,

represents the effect of the rotor passing through the stator's magnetic field. The effective resistance of the rotor,  , is composed of the equivalent value of the machine's power and the ohmic resistance of the stator windings and squirrel cage.

, is composed of the equivalent value of the machine's power and the ohmic resistance of the stator windings and squirrel cage.

The induction motor equivalent circuit when idle is approximately  , which is mostly reactive. Induction motors generally have a poor power factor, which can be improved by a compensation network.

, which is mostly reactive. Induction motors generally have a poor power factor, which can be improved by a compensation network.

The idle current draw is often near the rated current, due to the copper and core losses existing without load. In these conditions, this is usually more than half the power loss at the rated load. If the torque against the motor spindle is increased, the active current in the rotor increases by  . Due to the construction of the induction motor, the two resistances induce magnetic flux, in contrast to synchronous machines where it is induced only by the reactive current in the stator windings.

. Due to the construction of the induction motor, the two resistances induce magnetic flux, in contrast to synchronous machines where it is induced only by the reactive current in the stator windings.

The current produces a voltage drop in the cage factor of  and a slightly higher one in the stator windings. Hence, the losses increase faster in the rotor than in the stator.

and a slightly higher one in the stator windings. Hence, the losses increase faster in the rotor than in the stator.  and the copper factor of

and the copper factor of  both cause

both cause  losses, meaning the efficiency improves with increasing load and reduces with temperature.

losses, meaning the efficiency improves with increasing load and reduces with temperature.

gets smaller with smaller frequency and must be reduced by the delivered drive voltage. Thus,

gets smaller with smaller frequency and must be reduced by the delivered drive voltage. Thus,  increases engine power losses. In continuous operation, this is an approximation because a nominal torque generated by the cooling of the rotor and stator is not included in the calculation. Above the rated speed or frequency, induction motors are more effective at higher voltages. Today,

increases engine power losses. In continuous operation, this is an approximation because a nominal torque generated by the cooling of the rotor and stator is not included in the calculation. Above the rated speed or frequency, induction motors are more effective at higher voltages. Today,  and

and  are measured automatically and thus can be used on a motor to automatically configure itself and thus protect it from overload. Holding torques and speeds close to zero can be achieved with vector controls. There can be problems with cooling here, since the fan is usually mounted on the rotor.

are measured automatically and thus can be used on a motor to automatically configure itself and thus protect it from overload. Holding torques and speeds close to zero can be achieved with vector controls. There can be problems with cooling here, since the fan is usually mounted on the rotor.

Starting

A single phase induction motor is not self starting; thus, it is necessary to provide a starting circuit and associated start windings to give the initial rotation in a single phase induction motor. The normal running windings within such a motor motor can cause the rotor to turn in either direction, so the starting circuit determines the operating direction.

The four methods of starting an induction motor are direct on-line, reactor, auto-transformer and star-delta. Unlike a wound-rotor motor, the rotor circuit is inaccessible and it is not feasible to introduce extra resistance for starting or speed control.

For small single-phase shaded-pole motor of a few watts, starting is done by a shaded pole, with a turn of copper wire around part of the pole. The current induced in this turn lags behind the supply current, creating a delayed magnetic field around the shaded part of the pole face. This imparts sufficient rotational character to start the motor. These motors are typically used in applications such as desk fans and record players, as the starting torque is very low and efficiency is not a problem.

Larger single phase motors have a second stator winding fed with out-of-phase current; such currents may be created by feeding the winding through a capacitor or having it have different values of inductance and resistance from the main winding. In some designs, the second winding is disconnected once the motor is up to speed, usually either by a centrifugal switch acting on weights on the motor shaft or a thermistor which heats up and increases its resistance, reducing the current through the second winding to an insignificant level. Other designs keep the second winding on when running, improving torque.

Polyphase motors have rotor bars shaped to give different speed/torque characteristics. The current distribution within the rotor bars varies depending on the frequency of the inducted current. At standstill, the rotor current is the same frequency as the stator current, and tends to travel at the outermost parts of the squirrel-cage rotor bars. As the rotor accelerates, the slip frequency declines, and current tends to travel deeper within the squirrel cage bars. Polyphase motors can generate torque from standstill, so no extra mechanism is required to initiate rotation. The different bar shapes can give usefully different speed/torque characteristics as well as some control over the inrush current at startup.

Linear induction motor

A linear induction motor (LIM) is an AC asynchronous linear motor that works by the same general principles as other induction motors but which has been designed to directly produce motion in a straight line.

Linear motors frequently run on a 3 phase power supply.

Their uses include magnetic levitation, linear propulsion, and linear actuators. They have also been used for pumping liquid metals.[12]

Sources

- Henri Boy de la Tour (1906). The induction motor: its theory and design, set forth by a practical method of calculation. Translated Cyprien Odilon Mailloux. McGraw Pub. Co.. http://books.google.com/books?id=hbM_AAAAYAAJ&printsec=frontcover&dq=induction+motor&source=bl&ots=_JgDsnjN2s&sig=LHXibhTQ9XXIOvzsWATRSHA-xkA&hl=en&ei=X1O3TOekFpCisAPomqGeCQ&sa=X&oi=book_result&ct=result&resnum=14&sqi=2&ved=0CFoQ6AEwDQ#v=onepage&q&f=false.

- Benjamin Franklin Bailey (1911). The induction motor. McGraw-Hill. http://books.google.com/books?id=r_dOAAAAMAAJ&printsec=frontcover&dq=induction+motor&source=bl&ots=g7Th09trR-&sig=onxjvgyC920oARs_LUDqnzV2kHg&hl=en&ei=1VS3TNTyNoKKlwfWwJ3MDA&sa=X&oi=book_result&ct=result&resnum=4&ved=0CDcQ6AEwAzgK#v=onepage&q&f=false.

- Bernhard Arthur Behrend (1901). The induction motor: A short treatise on its theory and design, with numerous experimental data and diagrams. Electrical world and engineer. http://books.google.com/books?id=ffpOAAAAMAAJ&printsec=frontcover&dq=induction+motor&source=bl&ots=AWJzYuRVCl&sig=Bm0VKBdRKgCfTPpeR5_YU3BCrso&hl=en&ei=1VS3TNTyNoKKlwfWwJ3MDA&sa=X&oi=book_result&ct=result&resnum=7&ved=0CEUQ6AEwBjgK#v=onepage&q&f=false.

References

- ^ Babbage, C. and Herschel, J.W.F. (1825) "Account of the repetition of M. Arago's experiments on the magnetism manifested by various substances during the act of rotation," Philosophical Transactions of the Royal Society of London, vol. 115, pages 467-496.

- ^ Silvanus Phillips Thompson, Polyphase electric currents and alternate-current motors (London, England : E. & F.N. Span, 1895), Page 84.

- ^ The Electrical Engineer. (1888). London: Biggs & Co. Pg., 239. [cf., "[...] new application of the alternating current in the production of rotary motion was made known almost simultaneously by two experimenters, Nikola Tesla and Galileo Ferraris, and the subject has attracted general attention from the fact that no commutator or connection of any kind with the armature was required."]

- ^ Prodigal Genius: The Life of Nikola Tesla. Pg 115

- ^ Galileo Ferraris, "Electromagnetic rotation with an alternating current," Electrican, Vol 36 [1885]. pg 360-75.

- ^ "Two-Phase Induction Motor" (2011), The Case Files: Nikola Tesla, The Franklin Institute.

- ^ "Induction (Asynchronous) Machines". http://www.ece.msstate.edu/~donohoe/ece3183asynchronous_synchronous_machines.pdf.

- ^ "Induction Motors" (2011), Electric Motors Reference Center, Machine Design, Penton Media, Inc.

- ^ TORQUE SLIP CHARACTERISTICS OF INDUCTION MOTOR By Avinash SrivastavaRavi Kumar (MTECH CAID MSRIT)

- ^ a b Herman, Stephen L. (2011). Alternating Current Fundamentals, 8th Ed.. USA: Cengage Learning. pp. 529-536. ISBN 1111039135. http://books.google.com/books?id=RRbIRBUQk-sC&pg=PA521&dq=squirrel+cage+motor+induction&hl=en&sa=X&ei=fwz7TqqmLY2OigKGuqCXDQ&ved=0CE0Q6AEwADgK#v=onepage&q=squirrel%20cage%20motor%20induction&f=false.

- ^ a b Keljik, Jeffrey J. Keljik (2008). Electricity Four, 9th Ed.. Cengage Learning. pp. 112-115. ISBN 1435400313. http://books.google.com/books?id=y69O8PnwLbYC&pg=PA105&dq=squirrel+cage+motor+induction&hl=en&sa=X&ei=rP_6TqbTA6aciQLswMDQDg&ved=0CE4Q6AEwAA#v=onepage&q=squirrel%20cage%20motor%20induction&f=false.

- ^ http://books.google.co.uk/books?id=fgsAAAAAMBAJ&lpg=PA52&ots=NfAng_7A27&dq=einstein%20Linear%20induction%20motor&pg=PA52#v=onepage&q=einstein%20Linear%20induction%20motor&f=false

External links

- A drawing of an induction motor

- (Italian) Rotating magnetic fields: interactive

- Construct your squirrelcage electromotor using povray

- [1] More on Induction Motor.

|

|||||||||||||||||||